The Moxness Facility and Equipment

Moxness - Precision Silicone Rubber Products.

Facility

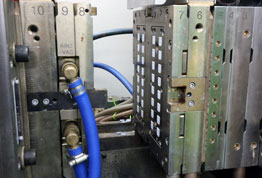

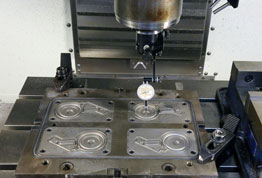

Moxness is a leader in the Liquid Silicone Rubber Molding industry and operates out of a 40,000-square-foot facility in East Troy, Wisconsin, that houses a tool building/mold maintenance shop, 13 LSR presses, 16 Transfer/Compression Presses, and 3 HCR Injection Presses. With various press styles and processes, the Moxness facility can manage short-run production, prototyping, and 24/7 Fully Automated Robotic Production. Overmolding to substrates like metal, various plastic and other elastomers is also one of our specialties.

High Consistency Rubber (HCR) Molding

Since the inception of Moxness we have been a leader in the compression, transfer and injection molding of High Consistency Rubber silicones. With available presses ranging from 50 tons to 500 tons with a variety of plate sizes and configuration options we can handle all of your molding requirements.

Special Elastomer (SE) Molding

Over the years, Special Elastomer Molding has been adapted into other applications that encompass elastomers like: Fluoroelastomer, HNBR, Nitrile, EPDM, Polychloroprene and many others. Overmolding onto various substrates is all done with these elastomers, providing Moxness with wasteless, flashless molding techniques.